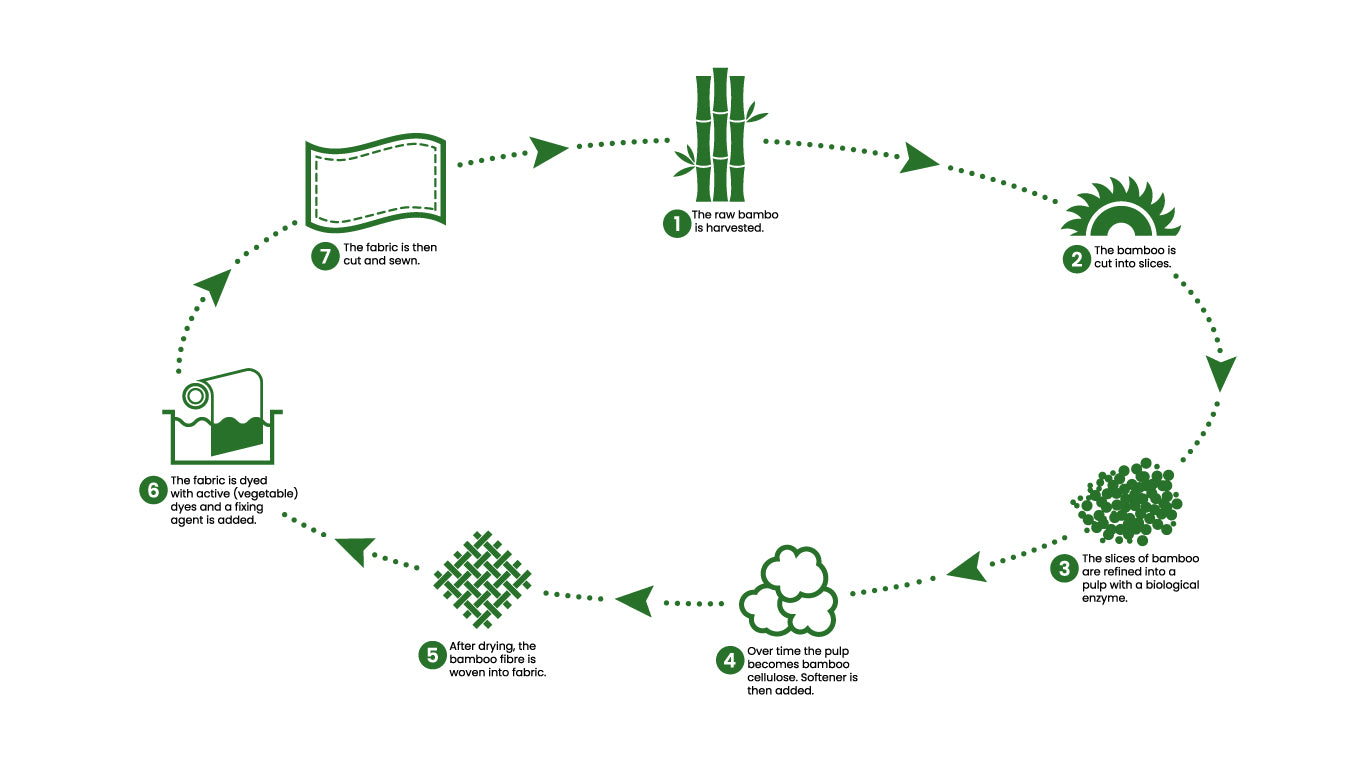

How is our bamboo turned into fabric?

All bamboo used in the production of our product range grows naturally without the need for fertilisers or pesticides. Natural rainfall is sufficient for the bamboo to grow, and it is entirely sustainable and a renewable resource.

Our bamboo is harvested from the bamboo forests in Southeast Asia. These beautiful forests span hundreds of thousands of miles. China alone has over 500 species of bamboo covering 4.4 million hectares of land area, which is equivalent to the size of Switzerland. Bamboo is abundant throughout Southeast Asia; with its fast-growing properties, easy maintenance and its benefit to the environment, it would be silly not to switch to bamboo products.

The bamboo fabric used in all our products and the filling of our duvets and mattress protectors are fully biodegradable and can be composted at the end of its life.

Our products are made from 100% bamboo, organically grown and fed by natural rainfall. During the growth of this bamboo, no fertiliser, pesticides or herbicides are used.

How bamboo viscose is made?

Manufacturers of bamboo viscose take mechanically crushed bamboo leaves and stems and produce bamboo fibers using a wet-spun process.

The resulting regenerated bamboo fibers are then dissolved into “a diluted solution of sodium hydroxide” which creates a pulpy substance.1 This substance is then ripened, filtered, and degassed before being forced through spinneret nozzles into yet another diluted vat of solution, which hardens the substance. This process is done in a closed-loop system.

This substance is then cut into fibers and spun into bamboo fiber yarn.

Oh, and it does not affect the pandas.

The process of turning bamboo into the premium quality soft fabric: